What Is a Laser Cutter?

A laser cutter uses lasers to cut all types of designs and patterns into a material. Depending on the laser and the material, the laser might vaporize, melt or burn the material in order to create the design. If you’ve been wondering what a laser cutter is and why you’d use one, the simple answer is that it’s a great non-touch way to create highly intricate designs with precision.

Laser cutters are most often used on glass, wood, gemstone, paper, plastic and metal. This amazing technology is credited to Kumar Patel, who created the first Co2 laser in 1963. Despite being called a cutter, modern lasers are used to engrave, cut and mark materials.

Depending on what you want to do, you can choose between three different main types, including:

- 1. Crystal laser cutters – These cut through thicker materials, but the higher-power requirement means they wear out faster.

- 2. Co2 or gas laser cutters – These are powered by Co2 and other gases, such as helium and nitrogen. They’re cheaper and work well for multiple types of materials.

- 3. Fiber laser cutters – These use fiberglass and are often referred to as solid-state lasers. They work well for reflective materials and hold up longer than crystal laser cutters.

You’re probably asking yourself what are the laser cutter’s pros and cons. The biggest benefits include high precision, the ability to work with a wide range of materials and no risk of contamination. However, lasers understandably use a lot of energy. There’s also a risk of toxic emissions, depending on the material. Thicker materials are a bit harder to deal with and you may have some occasional burnt edges.

What Is a Laser 3D Printer?

What is a 3D printer and how does a laser come into play? These are reasonable questions. First, let’s talk about how 3D printing actually works. A 3D printer takes a CAD file or a 3D scan and uses it to form an item by adding thin layers of sintering powder or resin until the item is fully formed.

A laser 3D printer cures the resin into the hardened plastic you’re used to seeing on 3D printed objects. Thanks to its quick-printing abilities, you can print any custom component in just hours versus waiting weeks or months for a company to manufacture it using traditional methods.

As long as you can design it, a laser 3D printer can probably create it, even if it’s nearly impossible to make using standard molds.

Stereolithography 3D printers use lasers to cure resin, while Selective Laser Sintering 3D printers work with polymer powder to print objects particle by particle. The best part is that 3D printers are becoming more affordable.

3D Printers vs. Laser Cutters

Following the big laser cutter vs. 3D printer debate, which one should you choose? Both are used for creative and functional purposes. Whether you’re wanting to create amazing crafts or build necessary components, both can help you achieve this.

The most noticeable difference is the process the two use. 3D printers work by adding materials. Filaments are used to build an object from nothing. You can use different colors, textures and more. You can even build multiple pieces and assemble them. A laser cutter subtracts from a material. You’ll need a base material to cut, engrave or etch. For instance, you might start with a solid piece of glass and then engrave a sweet message to a loved one. Laser cutters come in a variety of strengths. Some can cut through even thicker materials, while others are designed mainly for cutting extremely thin materials, such as paper or thinner plastics.

When it comes to a laser cutter vs. 3D printer, the choice comes down to what you want to accomplish. If you want to work more with flat pieces that just need to be cut or etched, a laser cutter is ideal. For instance, if you’re making flat puzzles, a laser cutter works well. A 3D printer works better for projects that require odd shapes or when you need to build something from scratch. A filament works as your base material and is gradually shaped into your final product.

One major thing to keep in mind is that laser cutters are typically faster. However, 3D printers are much faster than a typical manufacturing mold, which produces objects in the traditional way.

In this case, there isn’t a right or wrong choice. Pick the one that works best for your needs or use both, so you can do it all.

How Would mCreate Assist You?

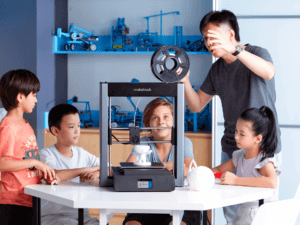

If you’re leaning more towards a 3D printer, the Makeblock mCreate 3D printer is a great place to start and is ideal for getting kids more interested in STEAM fields.

1. What is mCreate?

The mCreate 3D printer uses innovative technology to help bring creations to life. It’s designed for creativity and works well in a wide range of STEAM education applications. Not only does the printer feature a high print-quality rate, but you can switch to the laser engraving mode for even more types of projects.

2. Main Features of mCreate

mCreate makes it easier to answer the laser cutter vs. 3D printer question. Makeblock added a laser engraving feature to make the mCreate a highly useful 2-in-1 model.

1. Genius Smart Leveling

The feature that stands out the most is the Genius Smart Leveling. By using AI technology, mCreate better calculates the full working plan for the more accurate and reliable 3D printing. Without proper leveling, you might not get the right adhesion with the first print layer, which is critical to ensuring the print quality you want.

2. Smart Nozzle

The smart nozzle features a quiet cooling system, quick-change technology and an intelligent filament sensor. The filament sensor helps eliminate frustrating mistakes that happen when the filament runs out mid-project.

3. Flexible Magnetic Build Plate

The flexible magnetic build plate eliminates the hassle of scraping your finished product off the plate. The mCreate build plate is heatable. The magnetic sheet helps your object adhere better without any warping. Plus, when you’re done, you can remove the magnetic sheet and your item slides off easily.

4. Can Resume Printing after a Power Outage

Power outages won’t be a problem. The nozzle rises as soon as the power goes out to avoid damaging the partially printed object. When the power comes back on, printing resumes.

5. Versatile and User-Friendly Operating Tools

it’s easy to switch to the laser engraving mode, which even works on curved objects.

- 1. 3D Printing mode: Run the 3D slicing software called Cura, then install the plug-in for mCreate, and select “Makeblock” as the print device; the printing parameters will then be configured automatically. When Cura finishes slicing your model, it is ready for printing.

- 2. Laser Engraving Mode: With the software “Laserbox for mCreate”, you can process images, configure the engraving area and parameters, plan the optimal engraving pathway for each project, etc.

6. Laser Engraving on Curved Surfaces

A large build volume allows mCreate to engrave curved surfaces of solid objects of a certain height. Laser engraving can also be used for creative designs on food like cakes and chocolate. In addition, mCreate can engrave different materials, including paper, paperboard, wood board, corrugated paper, bamboo board, rubber board, leather, fabric, non-transparent acrylic, plastic, etc.

How Would Makeblock Laserbox Assist You?

If you prefer a laser cutter, the Makeblock Laserbox could be the perfect option. It can help bring your drawings to life.

1. What is Laserbox?

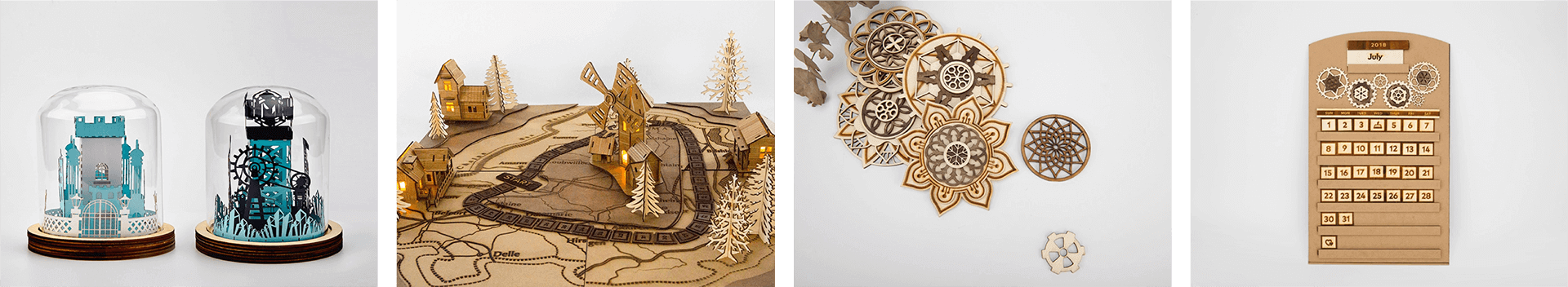

Laserbox has been designed with creation and education in mind. The laser cutter uses hand drawings to bring amazing creations to life, such as custom playmats, wooden toys, unique puzzles and more.

2. What are the Main Features of Laserbox?

Makeblock’s Laserbox laser cutter is easy to operate and works with a wide range of materials, such as paper, wood, rubber, plastic, leather and more. The 5 MP ultra-wide-angle camera works with Makeblock’s AI visual algorithm to auto-identify your material and program the right laser pathway. You can easily adjust where you want to cut or engrave. You can also pull a drawing from an object to use in other ways later.

You get to see the full path before you print. Autofocus modes eliminate complicated setups, but custom options are available. It’s all so easy to use, even children can use it. Jobs pause anytime the lid is opened.

Ready to bring your creations to life? With the right 3D printer and/or laser cutter, we can help. See Makeblock Official Website for the perfect tools and project ideas you need to get started.